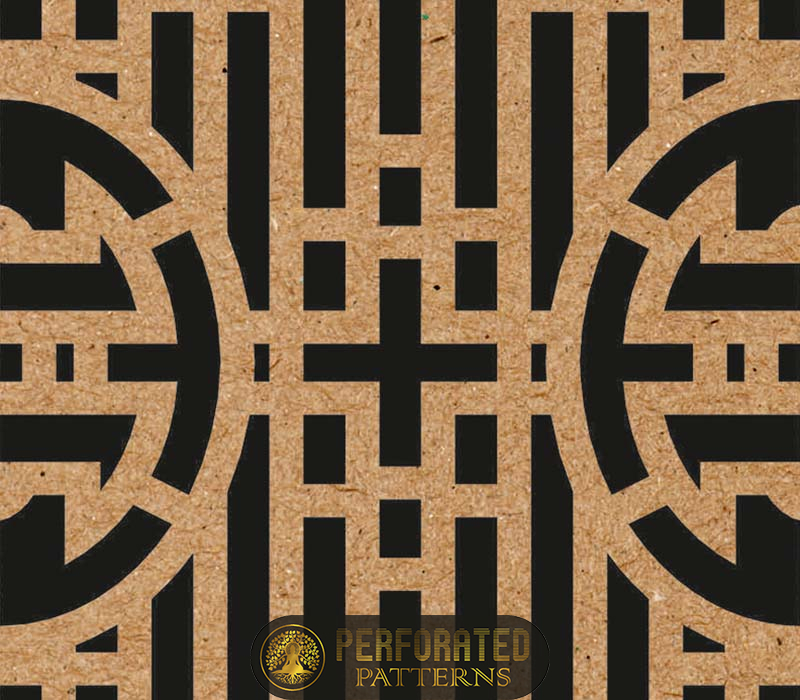

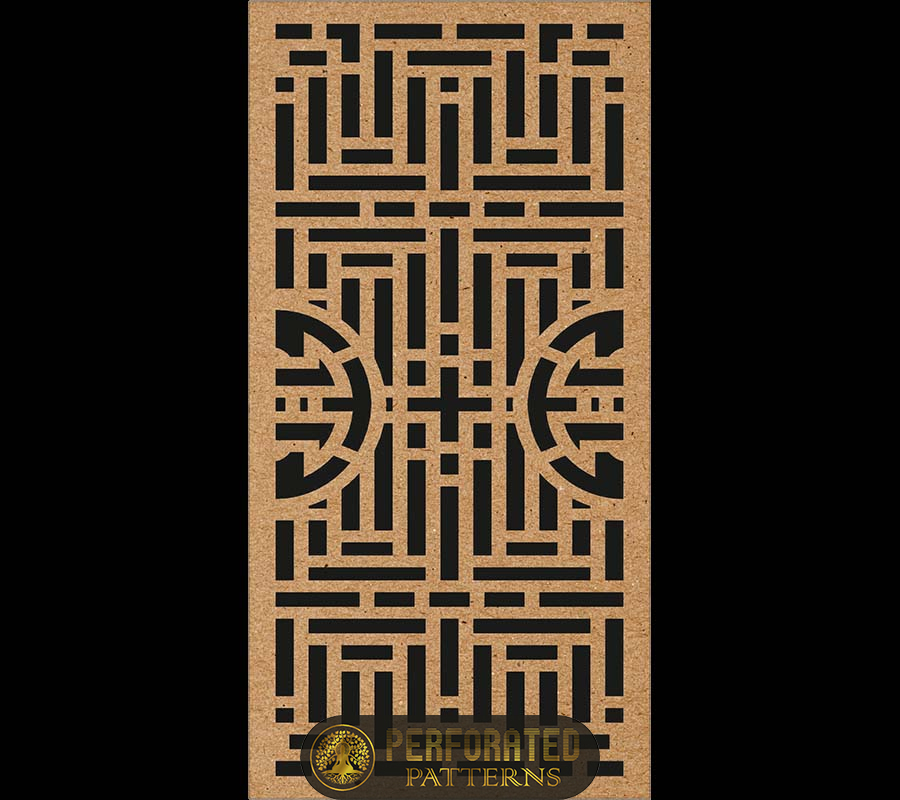

Geometric Pattern 4 Design Download

₹100.00 – ₹150.00

“Geometric Patterns for Laser & CNC Cutting” offers a collection of intricate designs optimized for precise cutting technologies. Ideal for various materials, these patterns range from simple shapes to complex motifs, enabling detailed and elegant results in projects. Perfect for crafting, decor, and industrial applications, enhancing creativity and precision.

Available File Formats to Download – JPG, CDR, EPS, DXF, SVG, PDF

Description

Reviews (0)

Description

| Dimensions | N/A |

|---|---|

| Size | Default Size, Custom Size |

| SKU | PP-GEO0004 |

| Category | Home Decor |

Geometric patterns are designs made up of shapes and forms that follow specific mathematical rules. These patterns are often characterized by their symmetry, repetition, and precise angles, making them ideal for use in laser and CNC cutting. The appeal of patterns lies in their ability to create visually stunning results while being highly adaptable to various materials and applications.

The Technology Behind Laser and CNC Cutting

Laser cutting and CNC cutting are advanced manufacturing techniques that rely on computer-controlled processes to achieve high precision and intricate detailing.

- Laser Cutting: This technique uses a high-powered laser beam to cut or engrave materials. The laser is guided by computer software, allowing for detailed and complex designs. Laser cutting is known for its ability to handle a wide range of materials, including metals, wood, acrylic, and fabric. Its precision ensures clean cuts and fine details, making it ideal for patterns.

- CNC Cutting: CNC cutting involves a computer-controlled machine that uses various tools (like routers or blades) to cut or shape materials. Unlike laser cutting, CNC cutting often involves physical tools and can handle larger volumes of material. CNC machines are versatile and can work with materials such as wood, plastics, and metals. The precision of CNC machines makes them well-suited for patterns, particularly for larger or more robust projects.

Applications of Geometric Patterns

Geometric patterns are versatile and can be applied across numerous fields and industries. Some notable applications include:

- Architectural Design: In architecture, patterns are used in facades, wall panels, and interior decor. They can create stunning visual effects and contribute to the overall aesthetic of a building. Laser and CNC cutting allow architects to incorporate complex designs into their projects, enhancing both functionality and beauty.

- Furniture Design: Designers use patterns to add unique elements to furniture pieces. Whether it’s for intricate inlays on wooden tables or decorative panels on cabinetry, designs can elevate the visual appeal and create a distinctive look.

- Art and Decoration: patterns are popular in art and home decor. They can be used for wall art, decorative screens, and even custom-designed jewelry. The precision of laser and CNC cutting ensures that these artistic creations maintain their intended design integrity.

- Industrial Applications: In industrial settings, patterns can be used for functional purposes such as ventilation grills, filters, and protective screens. The precision cutting offered by these technologies ensures that these components fit perfectly and perform effectively.

Design Considerations for Laser and CNC Cutting

When designing patterns for laser or CNC cutting, several factors must be considered to achieve optimal results:

- Material Selection: The choice of material can affect the outcome of the cutting process. Different materials have varying properties such as thickness, density, and heat tolerance, which can influence the cutting parameters and final result.

- Pattern Complexity: While complex patterns can create striking visuals, they may also require more precise and slower cutting processes. It’s essential to balance the intricacy of the design with the capabilities of the cutting technology to avoid issues like excessive heat or tool wear.

- Scale and Proportion: patterns should be designed with scale in mind. Small, intricate details might not translate well in larger applications, and vice versa. Proper scaling ensures that the patterns are both aesthetically pleasing and functional.

- Tolerances and Precision: Ensuring tight tolerances is crucial for achieving high-quality results. Both laser and CNC cutting technologies offer precision, but designers must account for potential variations and ensure that their patterns are designed to accommodate these factors.

Benefits of Geometric Patterns in Cutting Technologies

Geometric patterns offer several benefits when used in laser and CNC cutting:

- High Precision: The mathematical nature of geometric patterns aligns well with the precision capabilities of these cutting technologies, resulting in accurate and clean cuts.

- Efficiency: Laser and CNC cutting can efficiently produce complex patterns with minimal waste, making them cost-effective for large-scale production.

- Versatility: Geometric patterns can be adapted to various materials and applications, showcasing the flexibility of cutting technologies.

- Aesthetic Appeal: The symmetrical and repetitive nature of geometric patterns enhances the visual appeal of products and designs, making them highly desirable in artistic and commercial applications.

Reviews (0)

Leave a Reply

Reviews

There are no reviews yet.